Optimizing production and process planning

Team members at Ateleris helped evaluate suitable optimization techniques to optimize and increase the efficiency of production pipelines.

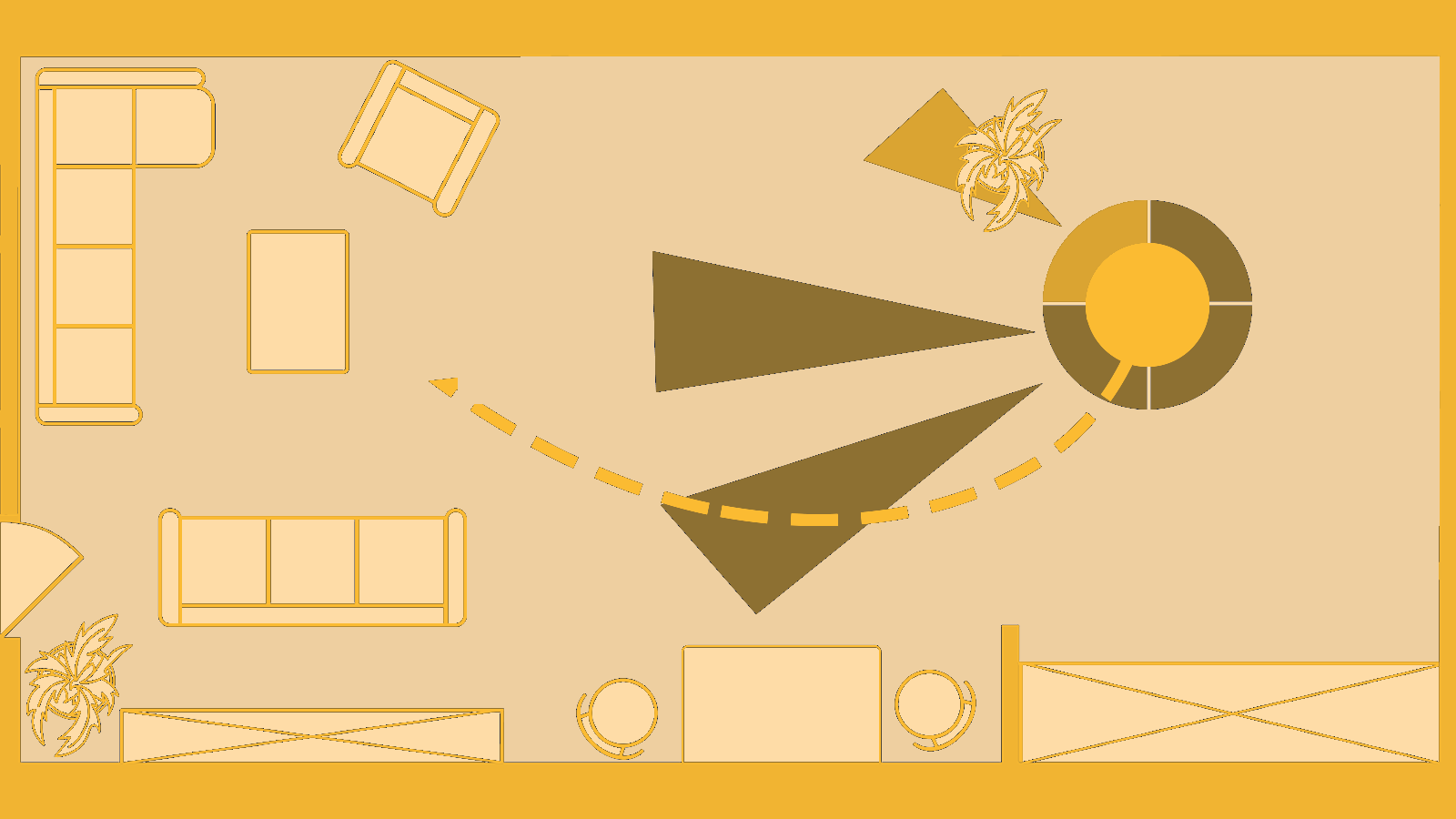

Every day, tons of food are shipped in Switzerland to thousands of shops. Shops expect their ordered products to arrive in pristine condition. Suppliers have to place items in the optimal order in boxes to prevent cotton candy from being squished by a family pack of spaghetti. To keep costs low, it is also essential to use the full capacity of boxes not to transport air. The limitations of the production line impose further constraints.

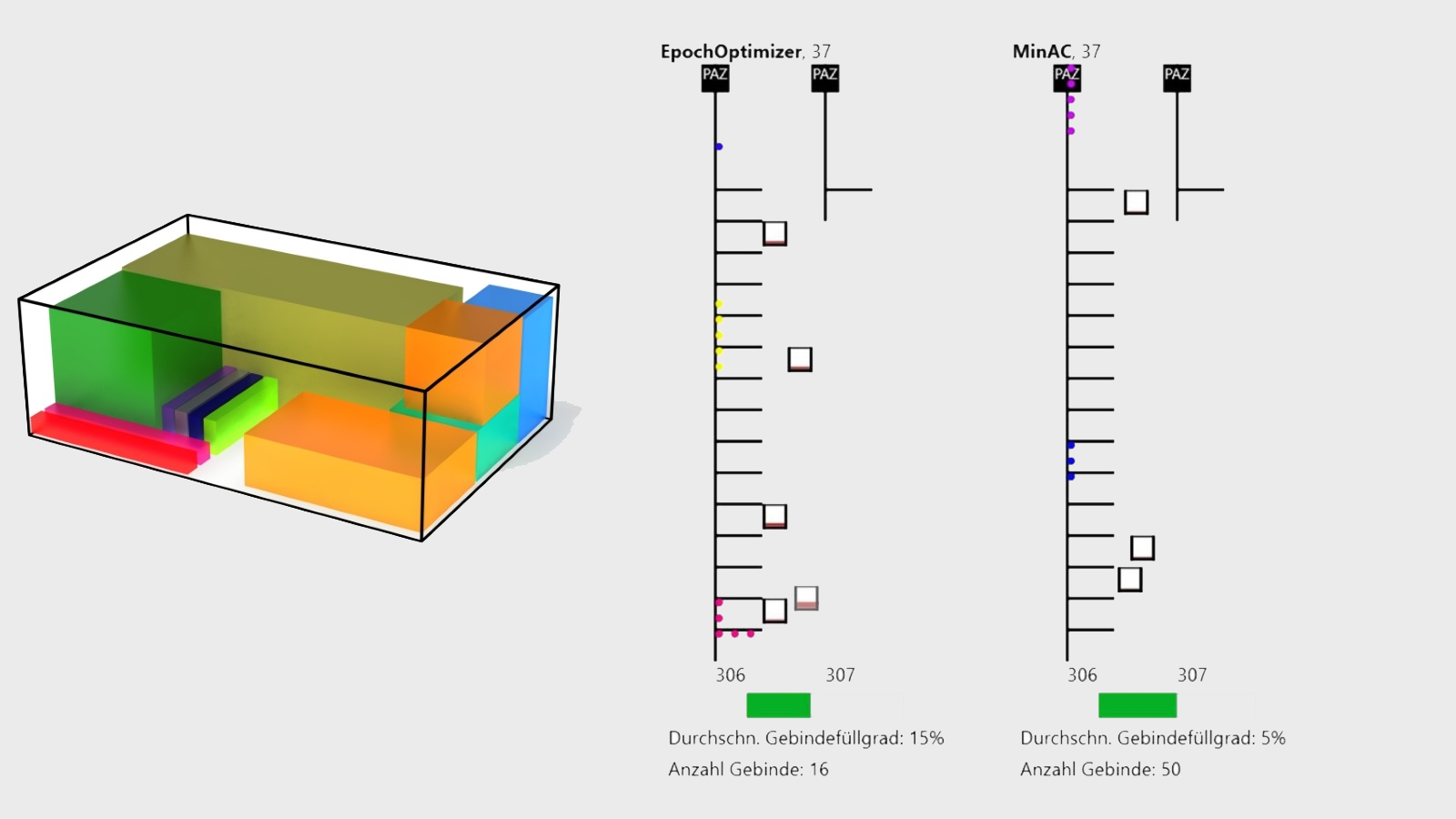

Our team has developed various optimization models and compared their performance. It achieved the best results with Mixed Integer Linear Programming (MILP), which increased the production line’s overall efficiency by over 10% without incurring additional costs.

Key Technologies/Terms

- Mixed Integer Linear Programming (MILP)

- Heuristic algorithms

- Visualizations

- C#/.NET